Tie Layer Use Case

Transforming Neurovascular Microcatheter Production

Innovative microcatheter technology and production techniques have enabled sophisticated treatments for patients with neurovascular conditions such as ischemic stroke and…

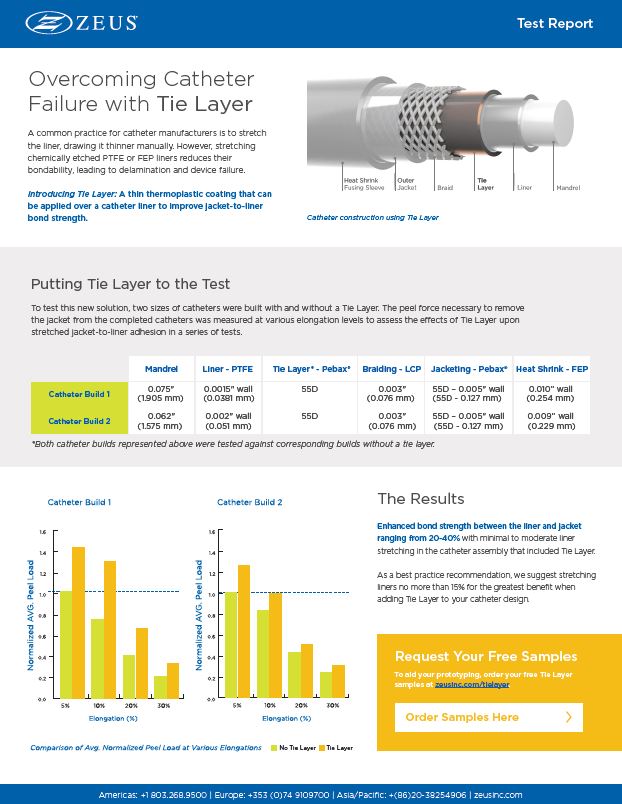

During catheter construction, many designs incorporate a supplemental layer added to the liner before braiding reinforcement is applied. This layer, frequently termed a tie layer, is a convenient method to enhance adhesion between layers. This is especially beneficial for catheter construction where delamination of layered components can be a significant failure.

Zeus tie layer is a thin polymer coating typically applied over PTFE or FEP liners during catheter construction. The tie layer is a fully melt-bondable surface that allows for full encapsulation of the braid during the jacket reflow process.

Tie layers are made from USP Class VI materials and may also be a good option for use with Zeus polyimide tubing. Strengthening catheter material adhesion can lead to fewer inspections, reduced production costs, and higher yields.

Innovative microcatheter technology and production techniques have enabled sophisticated treatments for patients with neurovascular conditions such as ischemic stroke and…

Advances in minimally invasive catheter-based procedures have transformed the management of many peripheral conditions. Catheter technology and production techniques are developing rapidly…

Testing the effects of tie layer on jacket-to-liner bond strength.