History of Zeus

Founded in 1966 and built on the principle belief that “There is no ‘good enough’ in true craftsmanship,” Zeus has journeyed through decades of relentless innovation on a never-ending quest to provide solutions that enable innovation and enhance lives.

As a world leader in advanced polymer solutions, Zeus is at the forefront of dynamic innovation, helping a range of industries transform ideas into reality. From aerospace and automotive applications to life-saving medical devices and more, our high-performance polymer componentry and cutting-edge catheter solutions help solve the critical needs of the future, enabling you to lead from the front.

Selected Zeus Milestones

1966 – After working for 10 years in the extrusion industry, Frank P. Tourville, Sr., founds Zeus in 1966 in Raritan, NJ. After acquiring his first extruder from Times Wire & Cable (Wallingford, Conn.), Mr. Tourville rents a facility and hires his first employee, Ray Coulombe. Together, these assets – both people and machines – form the foundation of what would become Mr. Tourville’s thriving business.

1968 – Zeus develops Sub-Lite-Wall™ tubing – a tubing with super-thin walls. In conjunction with this development, Zeus manufactures PTFE 4:1 heat shrink tubing for intravenous catheters for Jelco – a division of Johnson & Johnson – and one of Zeus’ first medical customers.

1972 – Mr. Tourville opens a second shift at Raritan. Zeus now has 17 employees working in production and related functions.

1976 – Mr. Tourville purchases the Raritan, NJ, plant and celebrates Zeus’ 10th anniversary. Bill Cook, of the Cook Group, Inc., flies from Indiana to New Jersey to pick up an urgently needed order of tubing. Mr. Tourville and National Sales Manager John Worley personally deliver the order to Cook at an airport; the act cements Zeus’ long-standing value of commitment to its customers – including the Cook Group, Inc. Also at this time, Zeus establishes its business model of forming collaborative relationships with customers focusing on the development of custom extrusions. This approach results in Zeus’ special products accounting for 70 % of sales by the 1980’s.

1977 – Zeus achieves Underwriters Laboratory (UL) approval for its products. Meanwhile, the Raritan plant produces automotive push-pull cables with filled abrasion-resistant tubing

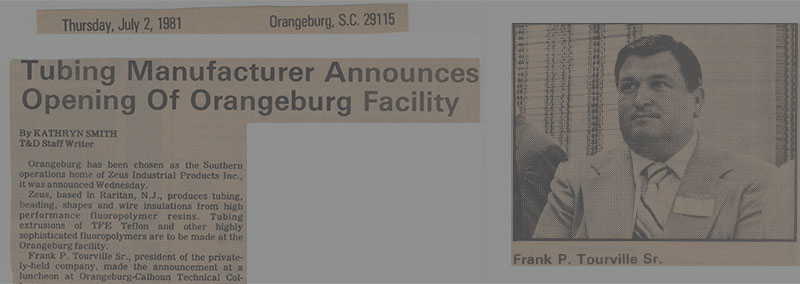

1981 – Mr. Tourville visits South Carolina with the State Development Board to look at potential facilities for expansion. A short time later, Zeus announces the purchase of a facility in Orangeburg, SC. The building is an 1897 Santee / South Carolina Cotton Mills building on the National Registry of Historic Places. A PTFE extruder is built for the Orangeburg site, and the first ten employees are trained at Orangeburg-Calhoun Technical College.

1982 – The Orangeburg, SC, facility opens with ten employees working a single shift. Barry Stewart serves as the first plant manager and Donald Kirby serves as the first production employee. In time, Zeus moves its headquarters to Orangeburg.

1989 – Executive Management and Sales offices relocate from the facility in Raritan, NJ, to Orangeburg, SC. Mr. Tourville becomes Chief Executive Officer, and John Worley is named President and Chief Operating Officer. Zeus also purchases a warehouse next to the Orangeburg plant and begins renovations for new Sales and Marketing offices.

1991 – Zeus celebrates 25 years in business, and Mr. Tourville is awarded the Key to the City of Orangeburg. PEEK extrusion process is also developed.

1994 – Zeus attends as an exhibitor at its first trade show, Medical Design & Manufacturing East in New York City.

1996 – A new facility, located in Gaston, SC, opens; and the first Zeus website launches.

1999 – A fourth facility opens in Aiken, SC, and expanded PTFE (ePTFE) process is developed.

2002 – A new Sales and Marketing building opens in Orangeburg, SC, located on Industrial Boulevard. Mr. Tourville is presented with DuPont’s prestigious M.I. “Whitey” Bro Lifetime Achievement Award in Fluoropolymers, “for his contribution as a foundational pioneer to the fluoropolymer tubing market.”

2005 – Zeus opens its first international location in Letterkenny, Ireland, giving the company a total of nine facilities at six sites and with over 1000 employees. Also during this time, the Aiken, SC, facility expands, and the Corporate Machine and Fabrication Shop doubles in size. Zeus’ Oracle-based ERP system is established.

2009 – Zeus attains AS9100 certification enabling the company to increase its presence in the aerospace and related industries.

2010 – Zeus achieves ISO Class 7 certification for its entire biomaterials facility.

2012 – Zeus’s Corporate Machine Shop receives AS9100:ISO9001 certification.

2013 – A new facility opens in Branchburg, NJ, replacing the original plant in Raritan.

2015 – Zeus launches its free Virtual Sample Locker service, an online portal where registered members can order samples quickly with expedited shipping. FluoroPEELZ™ peelable heat shrink, the most significant improvement for catheter construction in years, launches, and Zeus begins coating fiber optics. The Letterkenny, Ireland, facility also expands.

2016 – Liquid Crystal Polymer (LCP) monofilament is introduced as a replacement for metal braiding in catheter construction. The Letterkenny, Ireland, facility achieves TS16949 automotive certification.

2017 – Zeus launches the StreamLiner™ series of extruded PTFE catheter liners, the thinnest in the market. Featuring an impressive array of thin-wall and minimal ID/OD catheter liner options, these liners represent a new class of precision components that bring strength and flexibility for more advanced catheter designs.

2018 – Zeus announces a $76 million expansion that is expected to create an additional 350 jobs over the next several years. Soon thereafter, Zeus acquires Chattanooga-based MWC Technologies, LLC, adding polyimide manufacturing to the product portfolio that Zeus has been developing for the past 5 decades.

2019 – Zeus introduces Tie Layer, an adhesion aid for catheter construction that enhances jacket-to-liner bond strength. A new polyimide family of products is released, as well as Low-Temp Dual-Shrink™, FEP 2:1 heat shrink, and high-ratio FluoroPEELZ™ peelable heat shrink. Zeus opens a new, state-of-the-art facility in Columbia, SC, and acquires new manufacturing and office space to bolster operations in Tennessee.

2020 – StreamLiner™ Over-The-Wire (OTW) launches, bridging the gap between film-cast and free-extruded liner technologies, empowering design engineers to develop new and improved catheter solutions.

2021 – The polyimide family of products expands with the introduction of braid and coil reinforced polyimide tubing. Zeus acquires CathX Medical, a leading provider of catheter design and manufacturing services in San Jose, California. By integrating CathX capabilities, Zeus now offers end-to-end catheter solutions from components to completed assemblies.

2022 – Zeus introduces PTFE Sub-Lite-Wall™ multi-lumen tubing, an industry first, helping simplify the construction of steerable catheters. In response to rising demand, Zeus invests significantly in expanding the San Jose, CA, facility, greatly increasing its catheter design and manufacturing capacity.

2023 – The Arden Hills, Minnesota, facility opens, further expanding catheter design and manufacturing operations. Zeus launches Absorv™ XSE oriented bioabsorbable tubing, enabling next-generation bioresorbable scaffolds (BRS) for a wider variety of procedures.

2024 – Zeus enters a bold new chapter under the stewardship of EQT, a leading private equity firm, with newly appointed CEO Paddy O’Brien at the helm. This transition marks a pivotal moment in the company’s history, pairing EQT’s strategic investment and global perspective with Zeus’ innovation-driven culture to expand capabilities, accelerate growth, and unlock new opportunities.

2025 – StreamLiner™ NG, the company’s first-ever film-cast PTFE catheter liner, is unveiled, delivering next-level flexibility, mechanical performance, and reliability – reinforcing Zeus’ leadership in catheter component innovation.