Custom Etching

Fluoropolymers such as PTFE and FEP are prized for their high-performance properties and are also known for their low coefficient of friction. This highly lubricious feature allows them to excel in demanding applications such as vascular catheters, endoscopes, and other applications where little to no friction is desired.

However, the high lubriciousness of these polymers also makes it difficult for them to bond to other parts or finished goods using conventional methods and adhesives. Chemical etching is thus a preferred option when needing to bond these materials. Through our proprietary process, Zeus has pioneered the development of etched tubing, and we have developed a wide range of etching capabilities with unsurpassed contact angle measurements.

How Does It Work?

Etching is performed by placing the fluoropolymer tubing in a sodium solution. The resulting chemical reaction removes fluorine molecules from the carbon-fluorine backbone of the fluoropolymer, leaving carbon atoms that are deficient in electrons. When the etched surface of the material is exposed to air, oxygen molecules, water vapor, and hydrogen allow the restoration of the electrons. This restoration process results in a group of organic molecules that enable adhesion.

Will Etching Change the Properties of My Tubing?

The etching process penetrates only to a depth of a few angstroms (10-10 m); thus, the properties of the tubing remain mostly unaffected. However, the etching process will darken the surface of the material, usually to a brown or tan tint. Surface lubricity is also reduced by the etching process.

How Should I Store Etched Tubing?

Etched fluoropolymers will “grab” molecules from the air to repair their electron deficiency. This results in a weakening of the surface etching. For this reason, all etched materials should be stored in their original sealed bags. Zeus ships all etched tubing orders in sealed black UV-protective bags.

Does a Darker Color Mean a Better Etch?

Color is not a reliable indicator of etch quality. For this reason, Zeus includes etch certifications with each order shipped.

How is the Etch Tested?

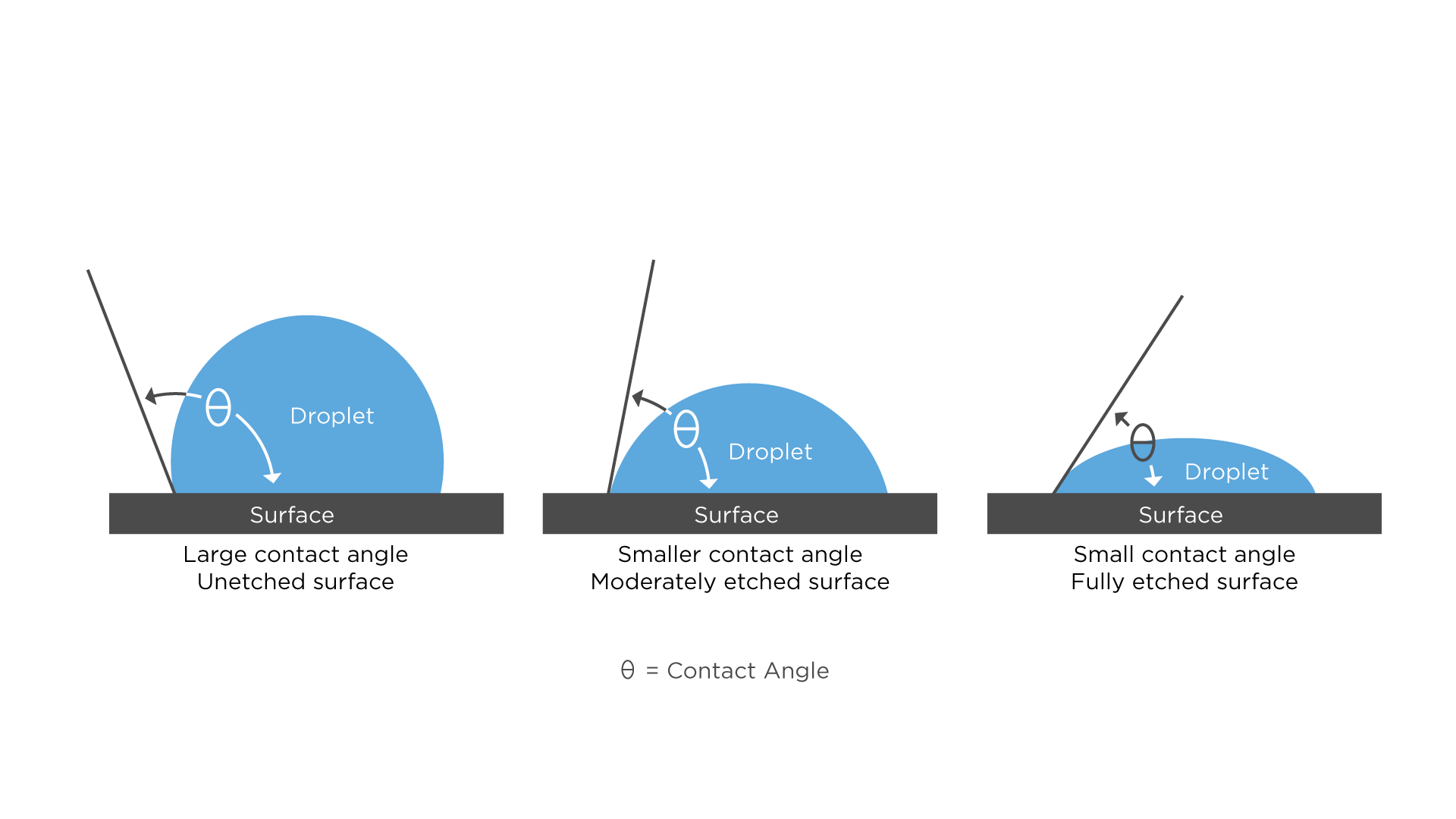

The etched material is tested via the contact angle method: This technique uses a goniometer and microscope to measure the angle of a sessile drop resting on a flat portion of the etched surface. Contact angle measurements of liquid droplets on substrate surfaces are used to characterize surface wettability. Chemical etching results in greater contact with droplets placed on the etched surface. The greater the contact with the droplet, the lower the contact angle between the droplet and the surface of the material, and the greater the bondability of the surface. Contact angle measurements provide a means to assess the degree of etching and the potential for bondability of the etched surface to other materials.

Surfaces that have been more thoroughly etched have increased wettability. Droplets placed upon etched surfaces show a reduced contact angle with the surface compared to less well-etched or un-etched surfaces.

Contact Angle

Zeus performs contact angle tests on all etched tubing orders and includes a Certificate of Compliance with the material. Test results are available by request.

Contact our team or call toll-free in the US 1-800-526-3842 or +1-803-268-9500 internationally today to see how we can develop a precision solution to give you a competitive advantage.