Projects

Filter by:

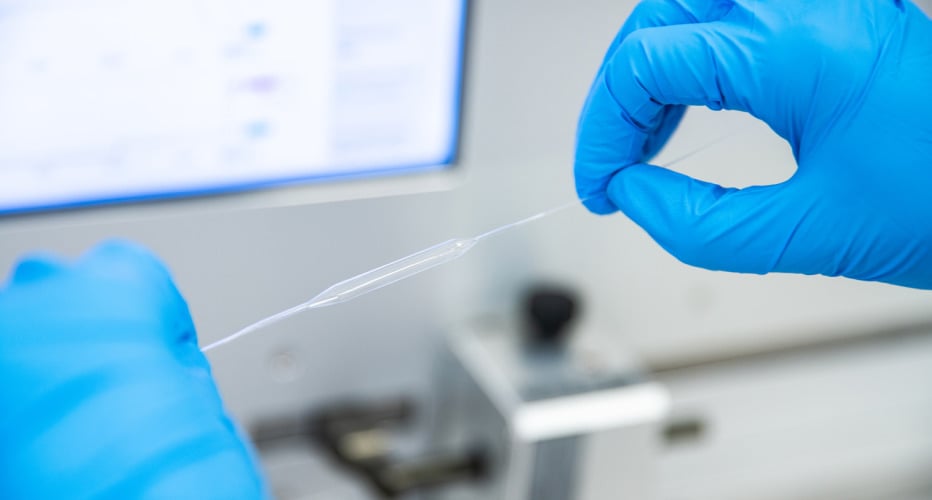

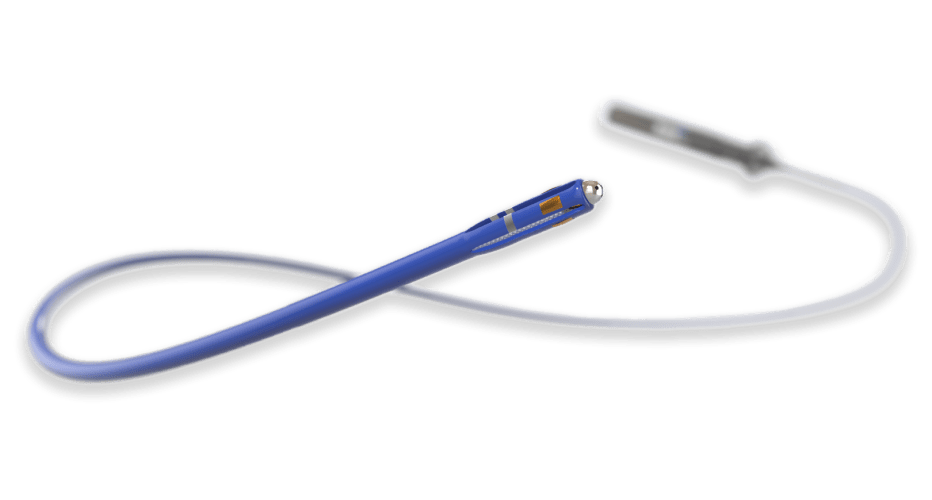

Steerable Delivery Catheter

Due to strict planarity for precise placement of an implant, the customer required an innovative catheter design solution.

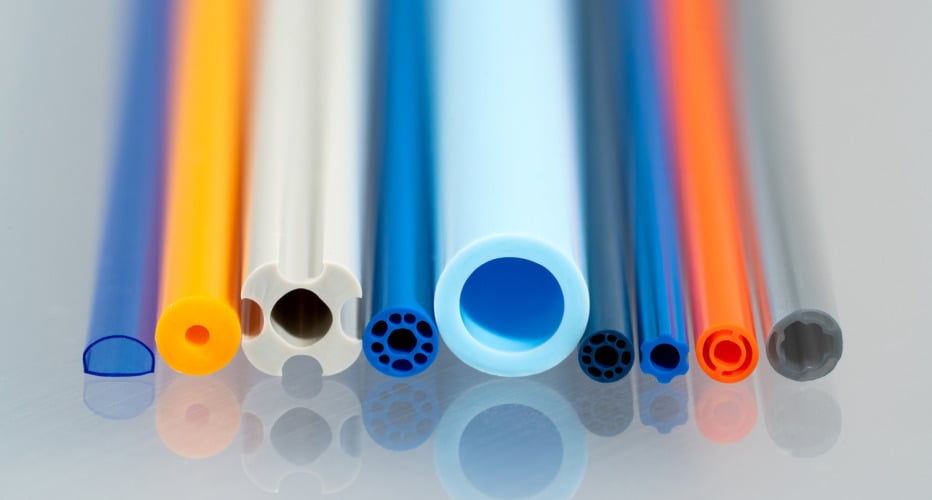

We developed a unique and highly specialized PTFE liner solution to aid the manufacture of the steerable catheter.

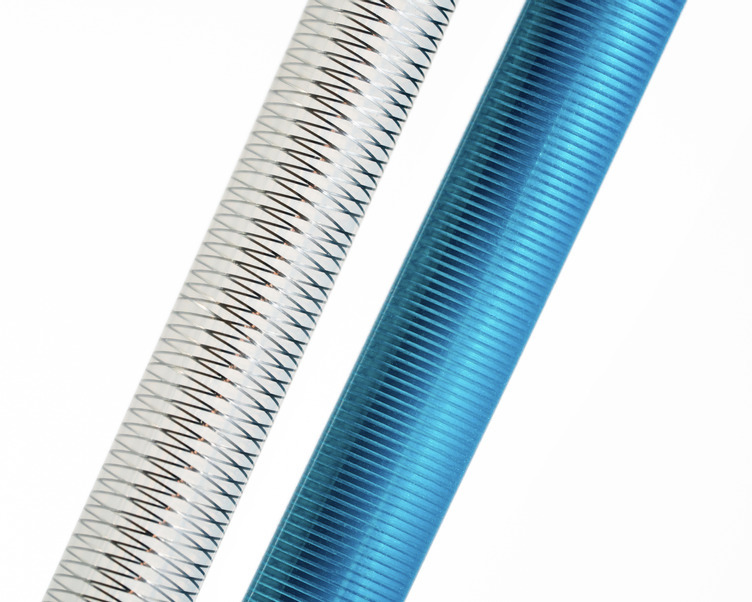

A custom braided catheter shaft integrates coils and laser-cut hypotubes to provide excellent steerability, flexibility, and torque response.

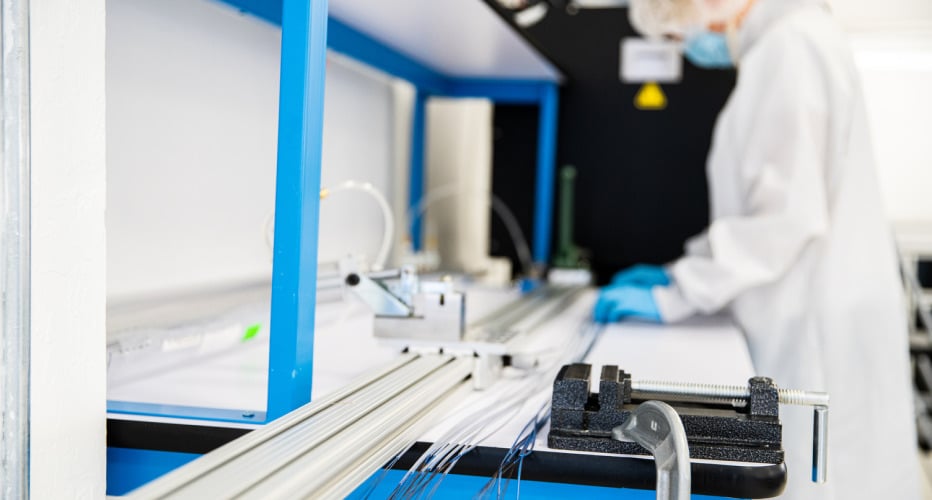

Every catheter engineer faces challenges with planarity of the final catheter. Keeping the articulated section of the catheter in-plane is critical for the physician to accurately and consistently use the device. Many variables during the manufacturing process can negatively affect the planarity.

We collaborated with our partners at Zeus to develop a unique and highly customized PTFE liner solution to aid the manufacture of the steerable catheter. This highly customized liner reduced manufacturing variation and delivered more consistent finished devices.

We supported the customer’s commercial product launch while minimizing variation in a robust manufacturing process. The capability to design and develop a custom liner for large-scale manufacturing was key to the program’s success.

“Their drive to understand our design needs and develop flexible manufacturing solutions is key to our NPI success.”

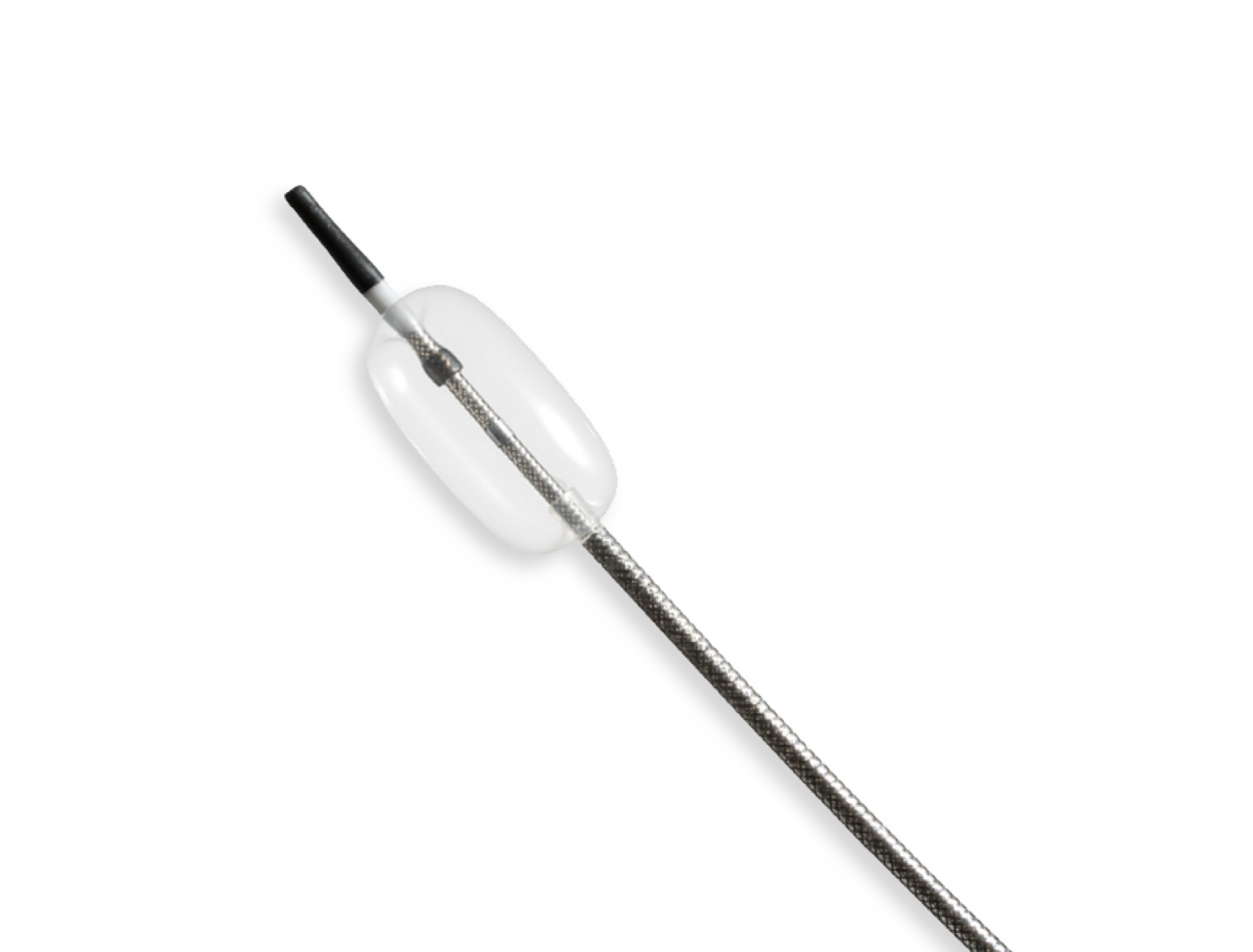

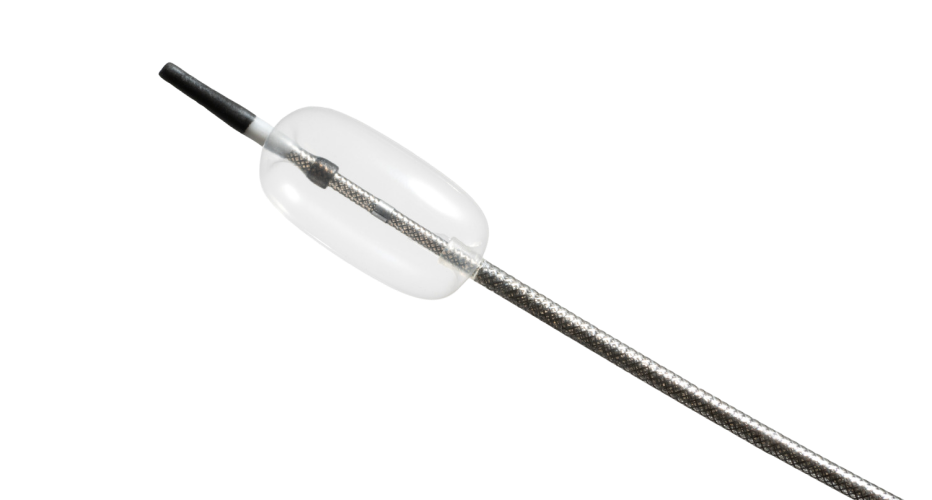

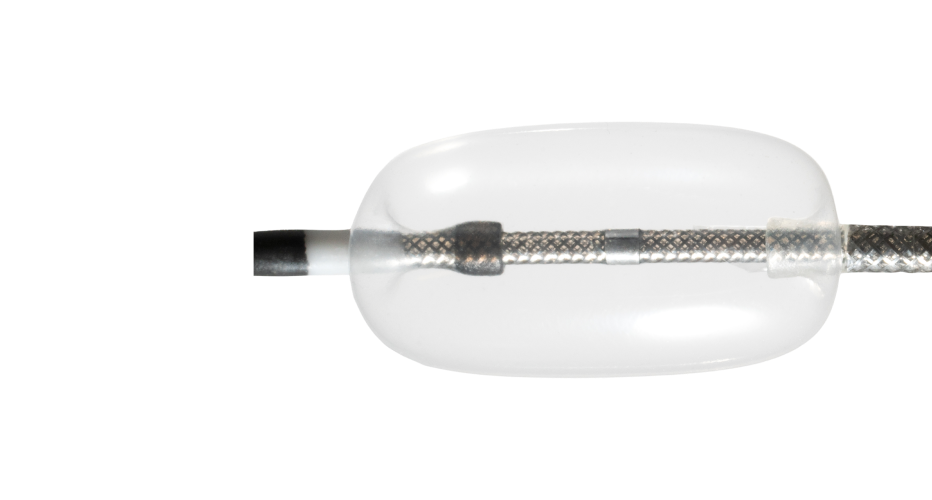

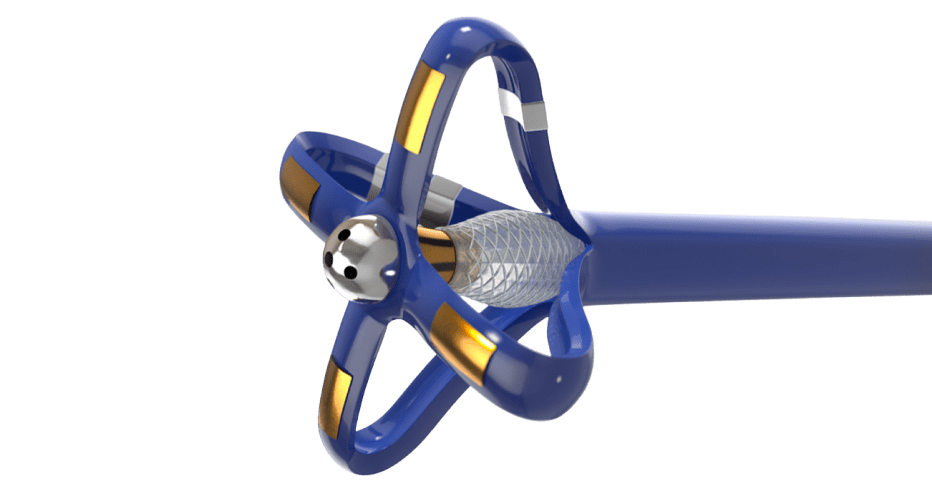

TAVR Delivery Catheter

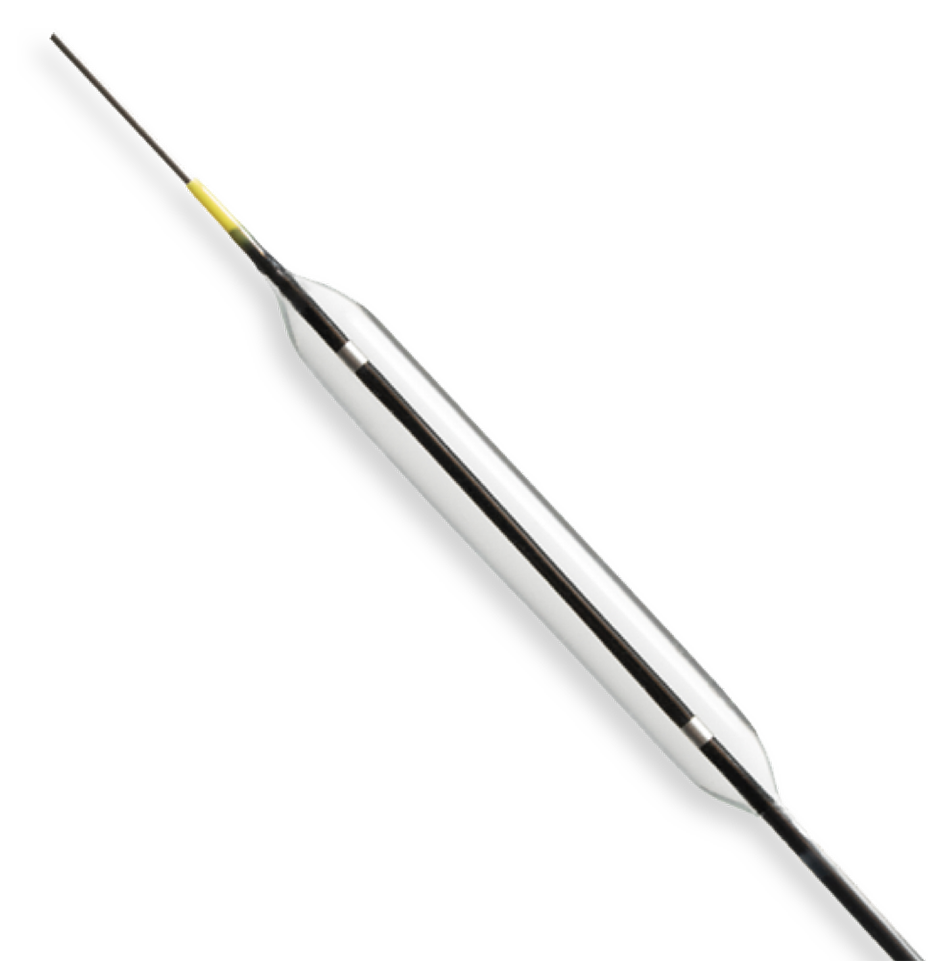

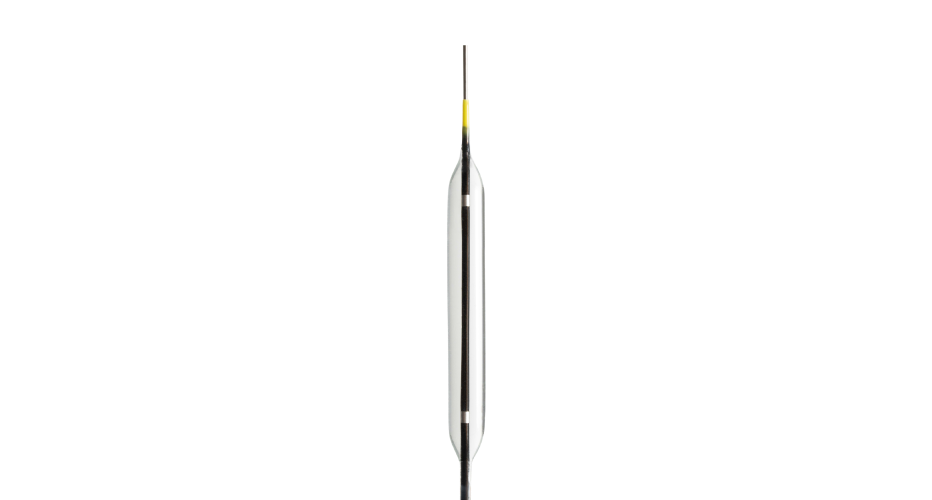

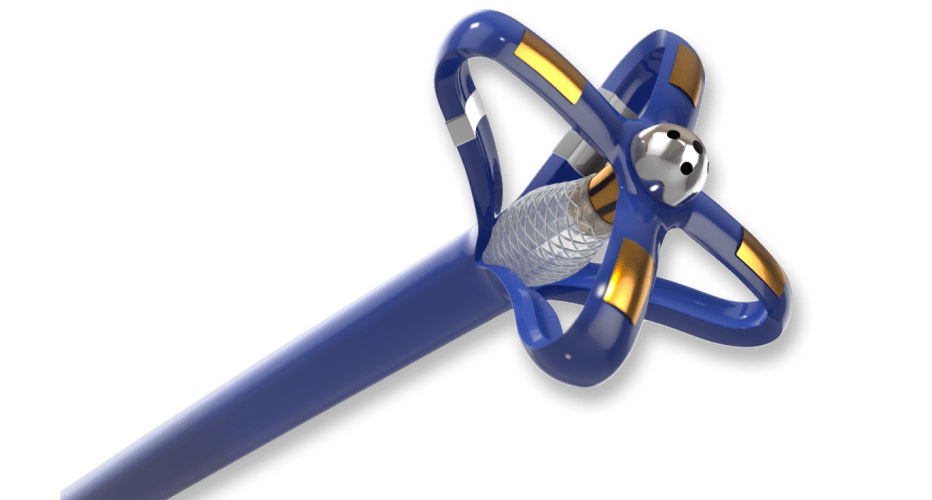

As the structural heart market innovates, design guidelines continue to become more challenging. Larger diameter catheters that track around tighter bends have created a need for unmatched weld strength in the pull ring assemblies that articulate the device.

This customer came to us with requirements for a minimal profile pull ring assembly that met very high weld strength with a CpK greater than 1.33.

Meeting the customer’s criteria for weld strength with a CpK greater than 1.33 required our team to review everything from material selection to pull ring design to process optimization. Nothing about this project was ordinary.

Our laser welding expertise and out-of-the-box thinking allowed us to design and manufacture a unique pull wire system that met the customer’s strict requirements.

With our advanced laser welding capabilities, the customer was able to develop a device that offers physicians unparalleled performance for the latest TAVR innovations.

“We came to them with a big ask, and they delivered. The expertise and creativity that they brought to this project was outstanding.”