Projects

Filter by:

Advanced Neurovascular Catheter

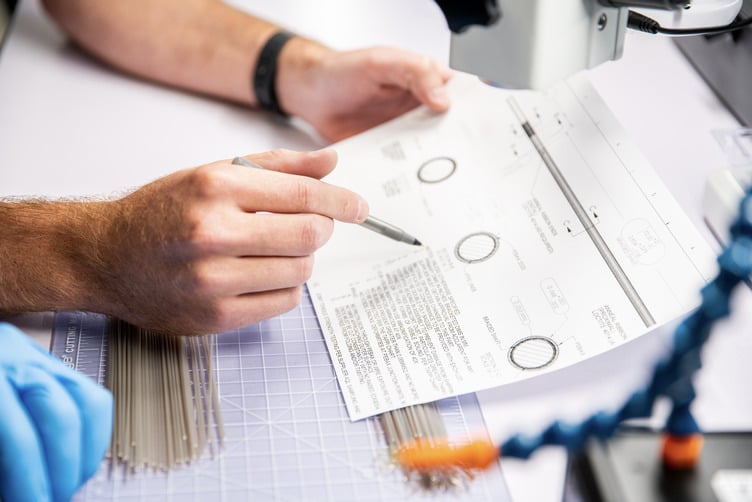

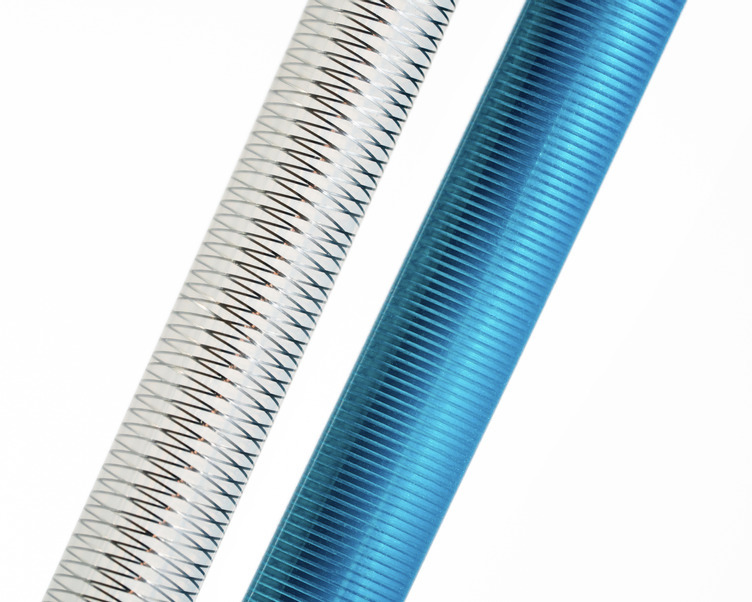

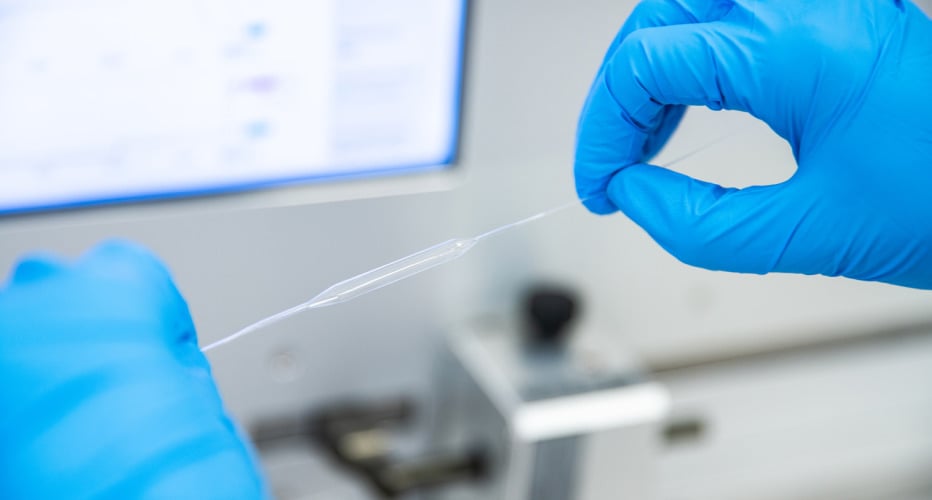

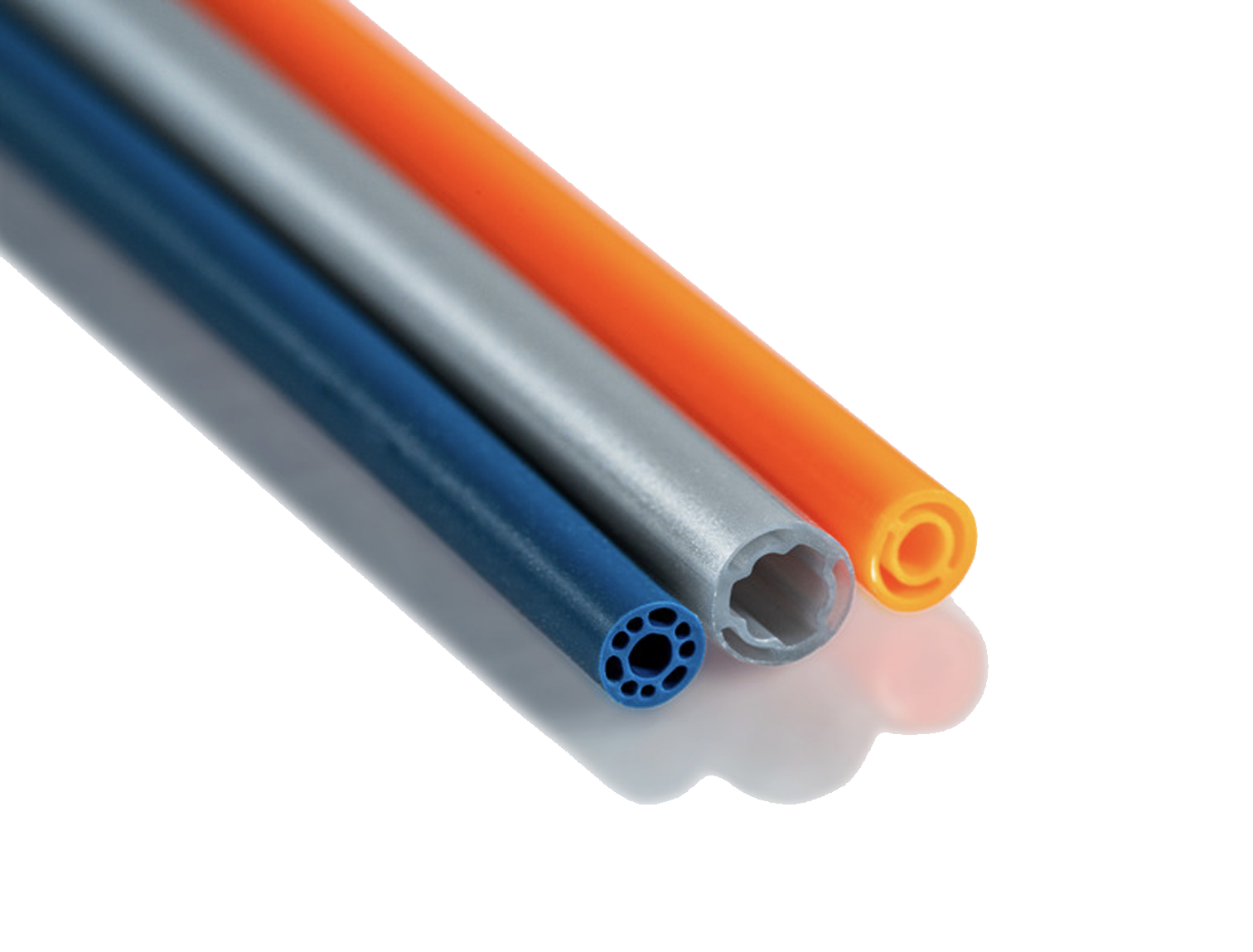

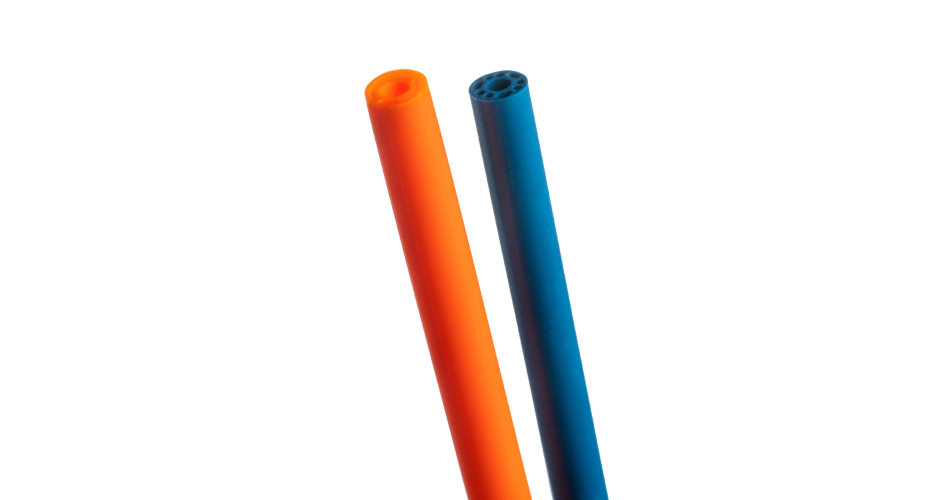

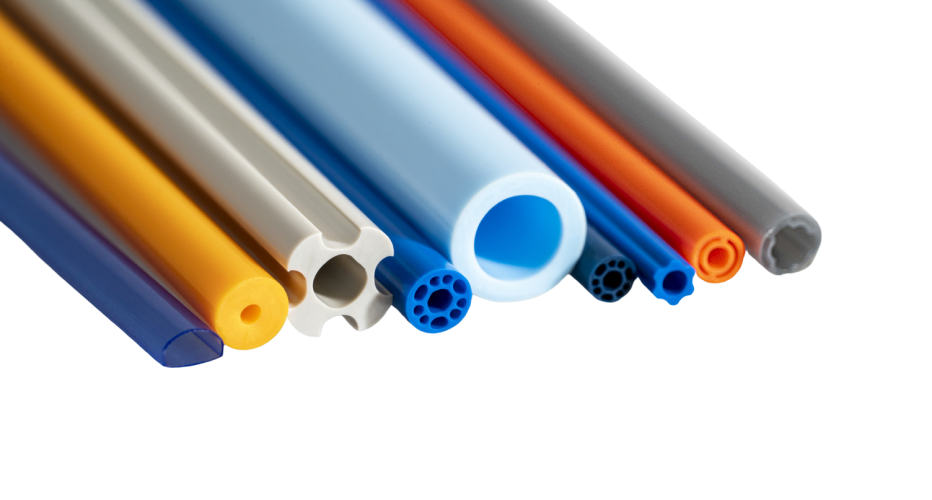

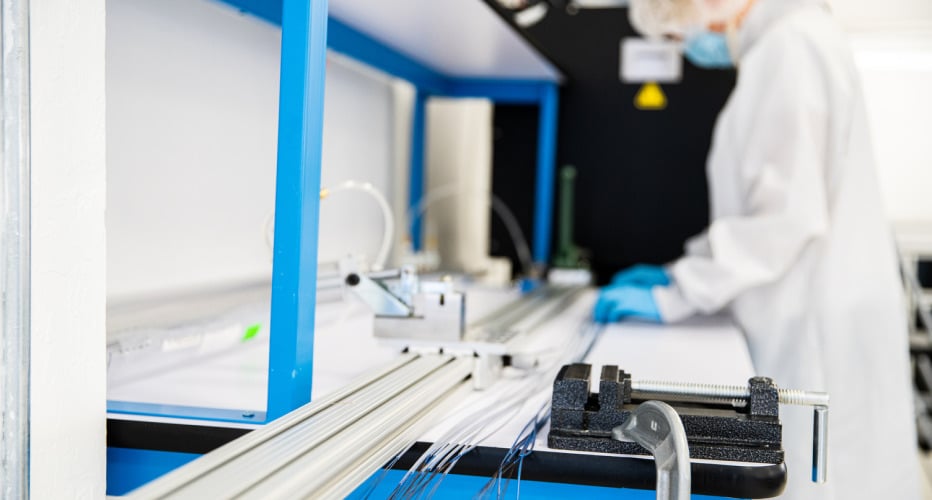

Working closely with the customer’s advanced R&D team, we developed a customized laser cut hypotube to serve as reinforcement for a cutting-edge neurovascular catheter.

We were able to translate the customer’s design guidance into a functional design and produce a hypotube that allowed specific flexibility along with the required torque translation to meet the customer’s requirements.

By utilizing our extensive inventory of in-stock material, we were able to meet the customer’s aggressive development timeline.

The customer’s design required a specific flexibility profile while meeting a torque translation requirement. These requirements were not being met with typical braid, coil, or laser cut hypotube patterns.

Our senior engineering team quickly developed several custom laser cut hypotube patterns that the customer could test and identify the exact pattern to meet their device requirements.

By quickly transforming design ideas into working prototypes, we allowed the customer to successfully move their project from the advanced R&D group into design verification, where we continue to support the customer’s product development process.

“Their ability to quickly understand our unique design requirements was key to moving this project forward. They are a great partner to work with.”

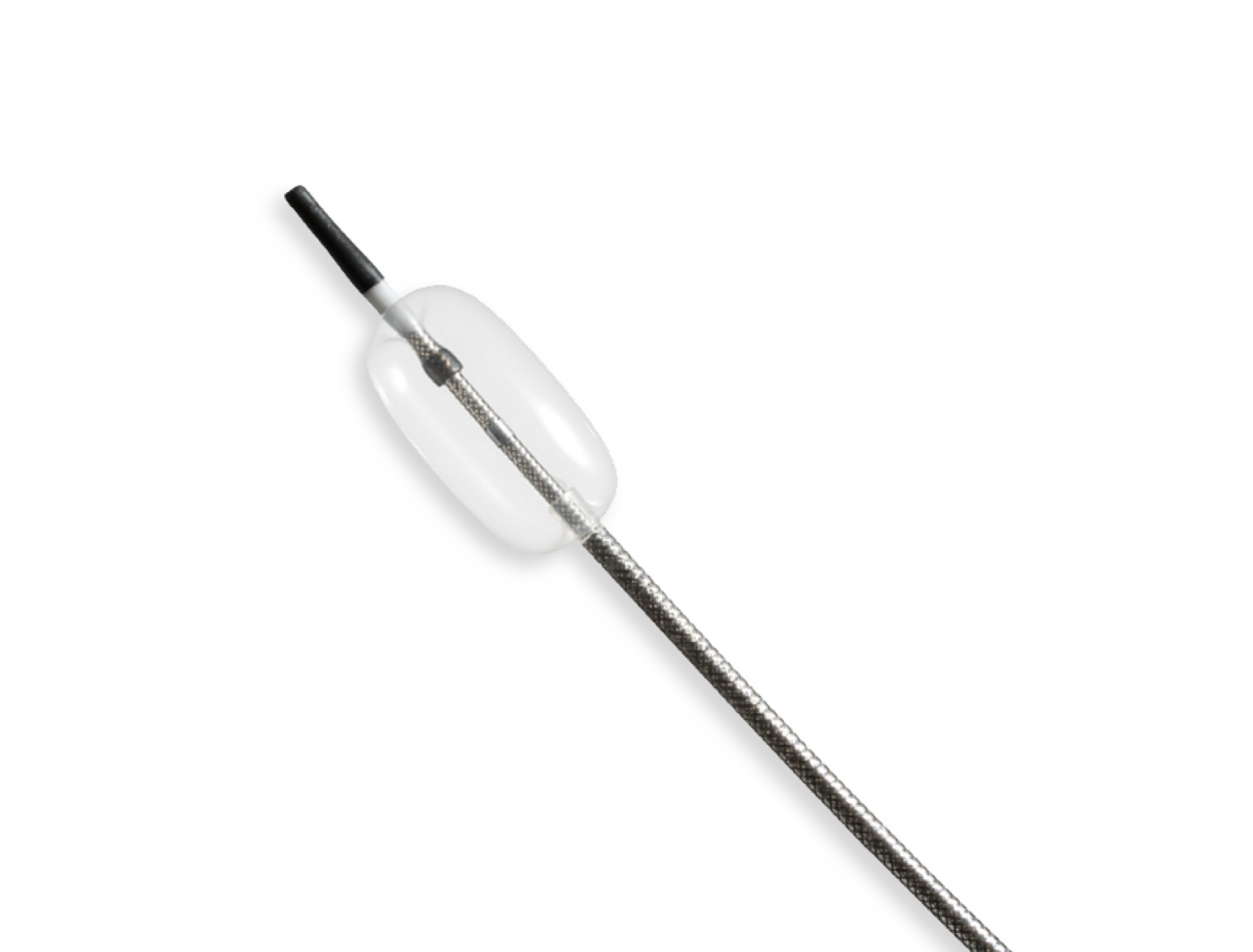

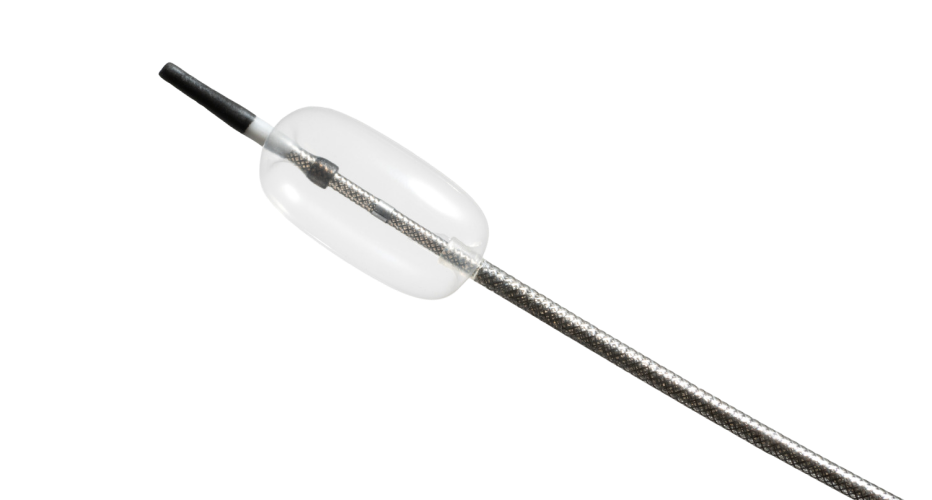

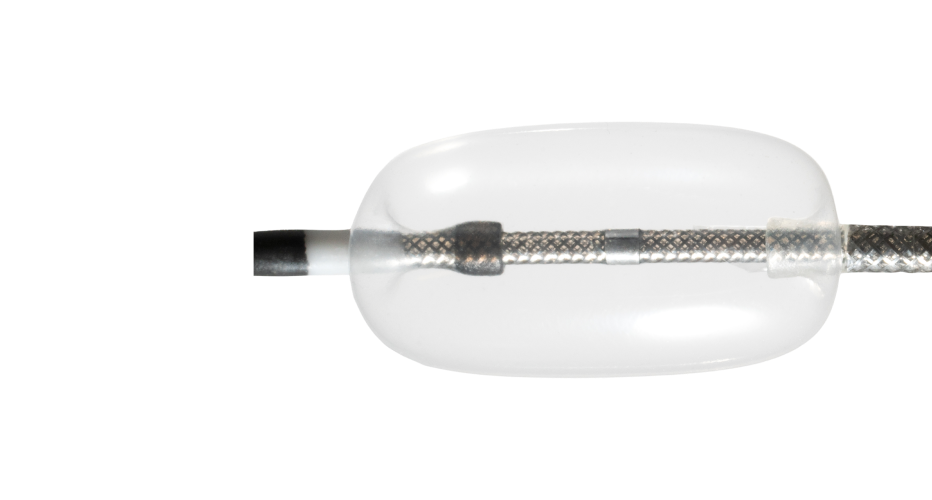

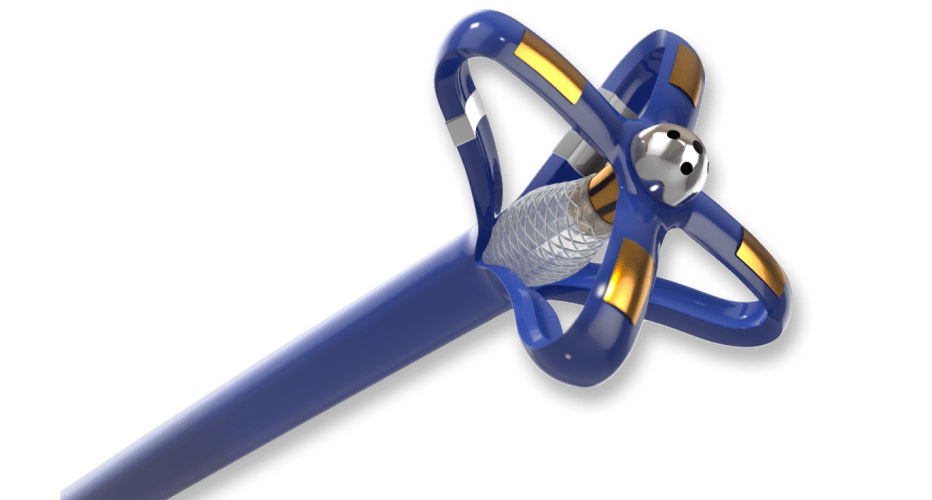

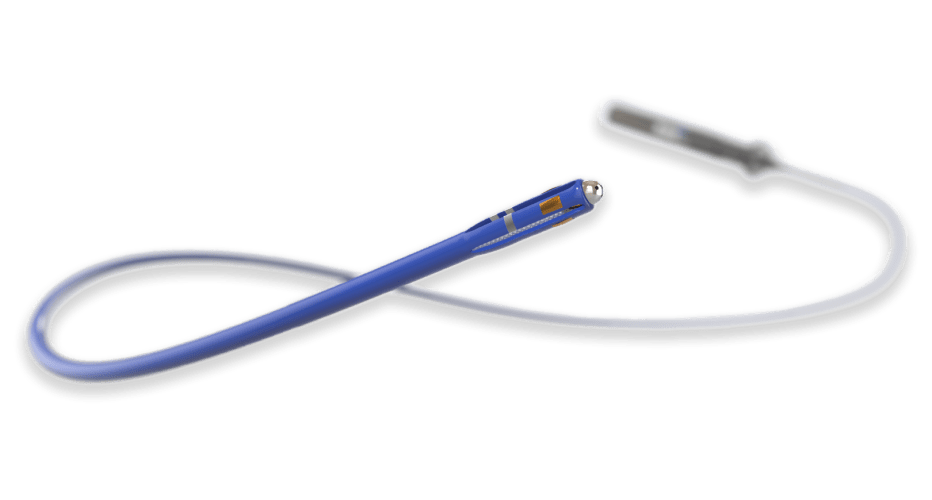

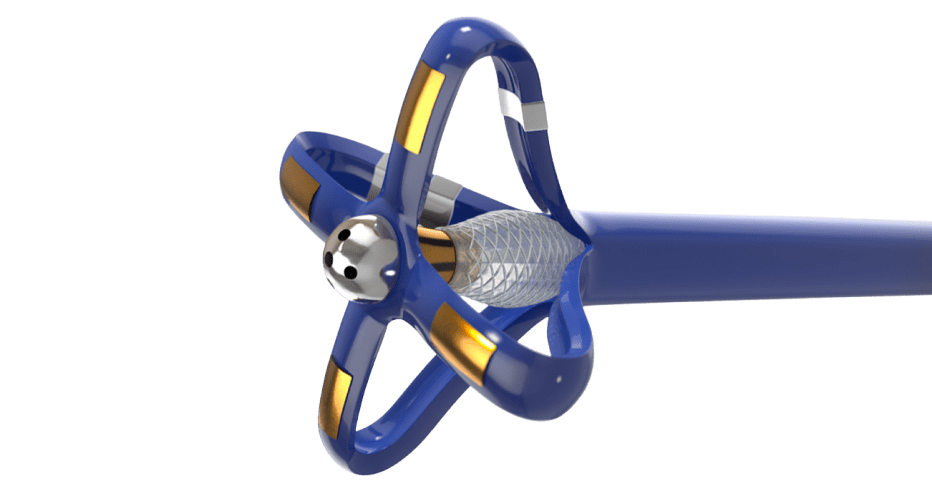

TAVR Delivery Catheter

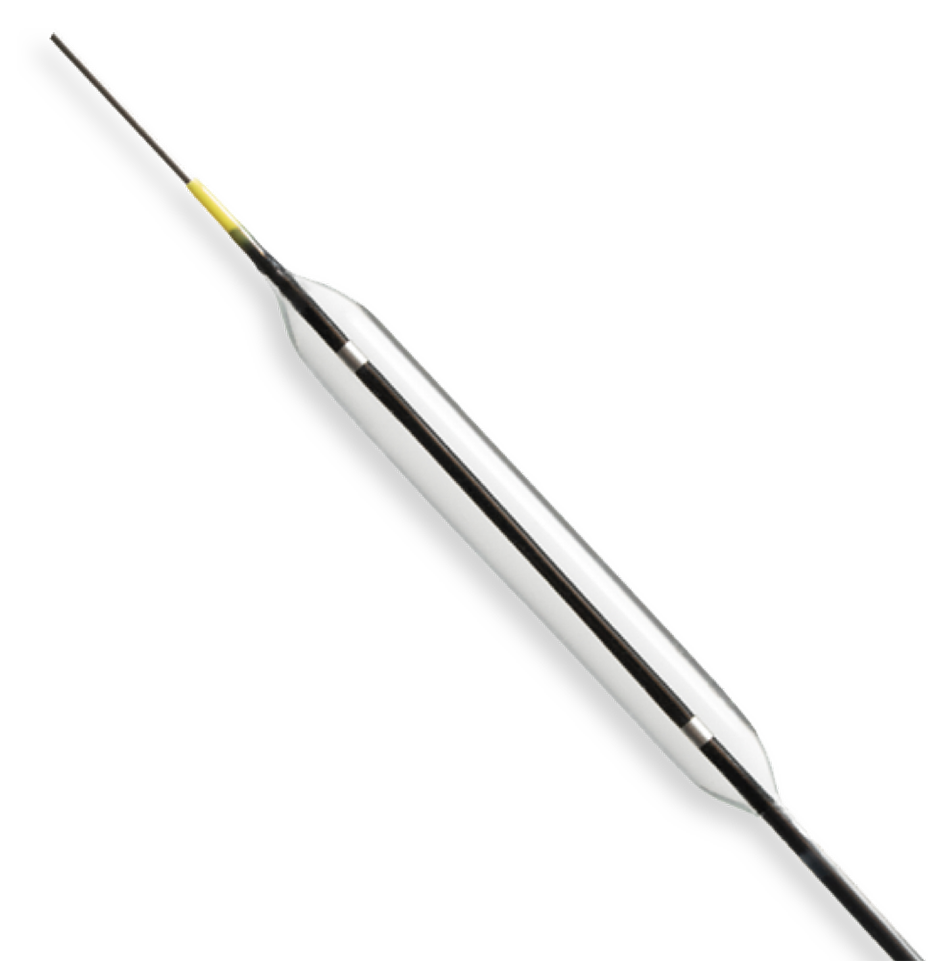

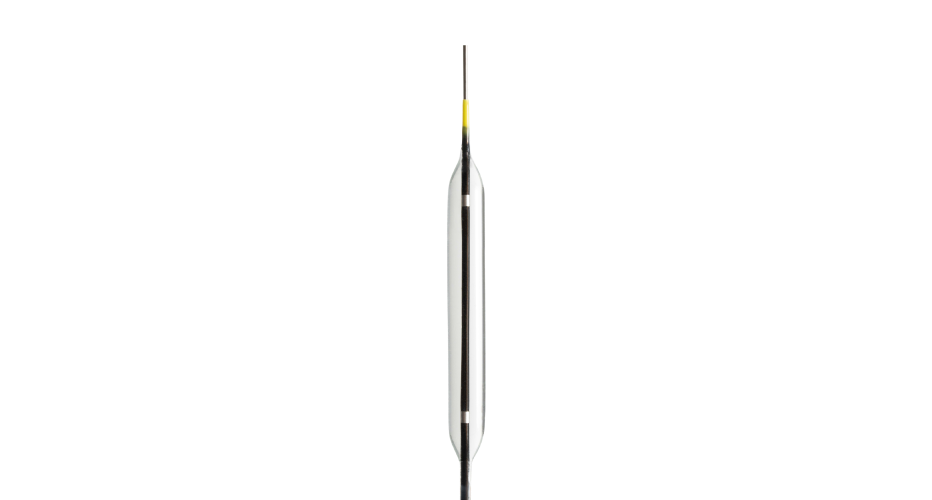

As the structural heart market innovates, design guidelines continue to become more challenging. Larger diameter catheters that track around tighter bends have created a need for unmatched weld strength in the pull ring assemblies that articulate the device.

This customer came to us with requirements for a minimal profile pull ring assembly that met very high weld strength with a CpK greater than 1.33.

Meeting the customer’s criteria for weld strength with a CpK greater than 1.33 required our team to review everything from material selection to pull ring design to process optimization. Nothing about this project was ordinary.

Our laser welding expertise and out-of-the-box thinking allowed us to design and manufacture a unique pull wire system that met the customer’s strict requirements.

With our advanced laser welding capabilities, the customer was able to develop a device that offers physicians unparalleled performance for the latest TAVR innovations.

“We came to them with a big ask, and they delivered. The expertise and creativity that they brought to this project was outstanding.”