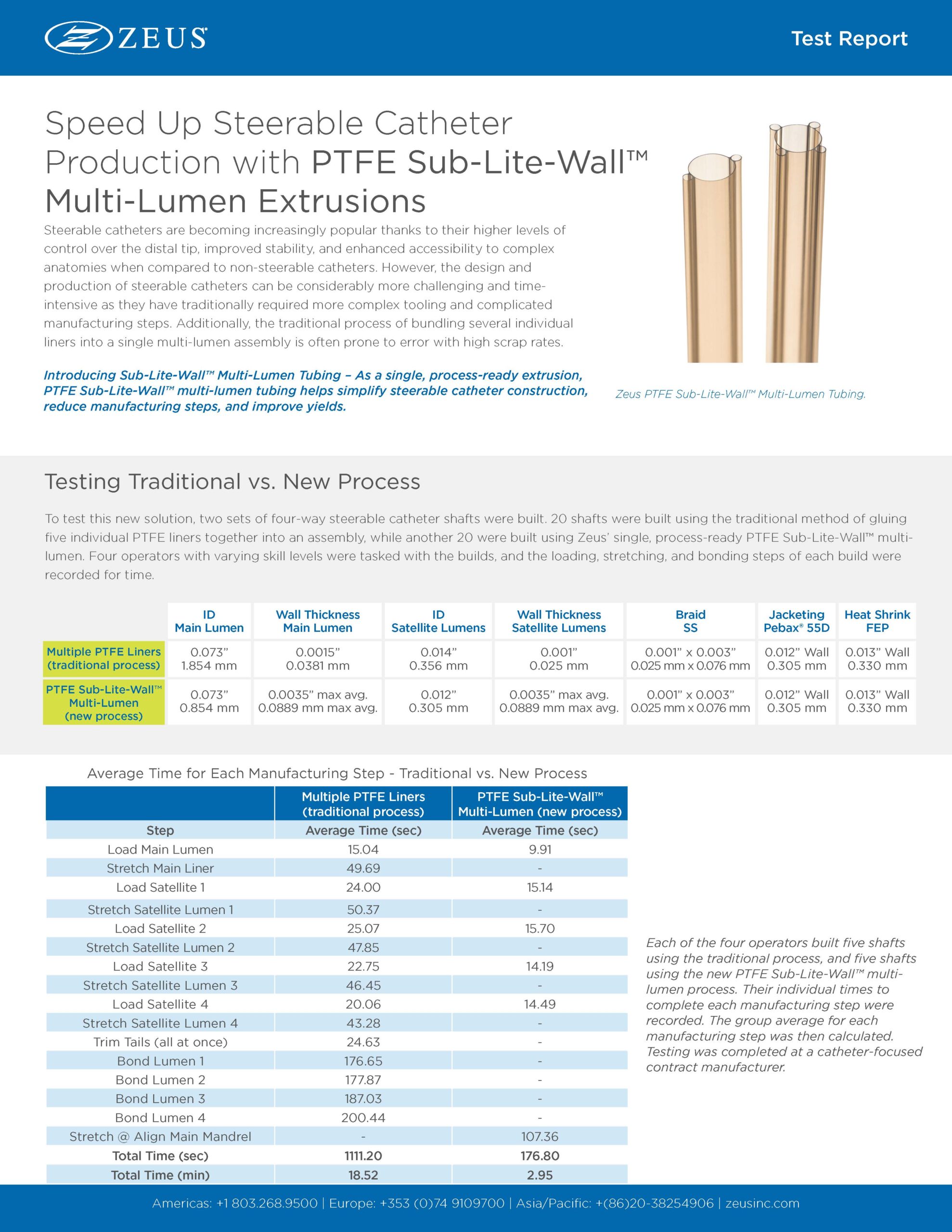

As a single, process-ready extrusion, PTFE Sub-Lite-Wall™ multi-lumen tubing helps simplify steerable catheter construction, reduce manufacturing steps, and improve yields.

Engineering steerable and deflectable catheters can be challenging, especially when manufacturers are required to procure and bundle several individual liners into a final catheter assembly. This delicate process can be time-consuming and is prone to error in both development and manufacturing settings.

Zeus PTFE Sub-Lite-Wall™ multi-lumen extrusions help simplify this process while eliminating multiple manufacturing steps and complex tooling by providing engineers a single, process-ready multi-lumen extrusion.

“Based on early evaluator feedback, the time to assemble a steerable catheter was greatly reduced to one-fifth of the traditional time.” – Rodrigo Silva, Product Manager, Zeus

Sub-Lite-Wall™ multi-lumen tubing consists of one large lumen with one to four smaller satellite lumens. As a part of our Sub-Lite-Wall™ family of ultra-thin-walled extrusions, PTFE Sub-Lite-Wall™ multi-lumens can be produced with average wall thicknesses ranging from 0.002” to 0.005” (0.051 mm to 0.127 mm).

Capabilities, sizing, properties, & more.

Speed up steerable catheter production with PTFE Sub-Lite-Wall™ multi-lumen tubing.