Polyimide & PI Glide™ Tubing

Zeus PI tubing can be produced in a range of ID sizes with thin walls and extremely tight tolerances. Its lightweight construction and exceptional mechanical properties make it well-suited for a host of medical device applications. When enhanced lubricity is required, PI Glide™, a PI/PTFE composite, provides up to 25% lower coefficient of friction over standard PI.

Key Benefits of PI & PI Glide™:

- Thin Walls & Tight Tolerances

- Exceptional Mechanical Properties

- Customizable Lubricity

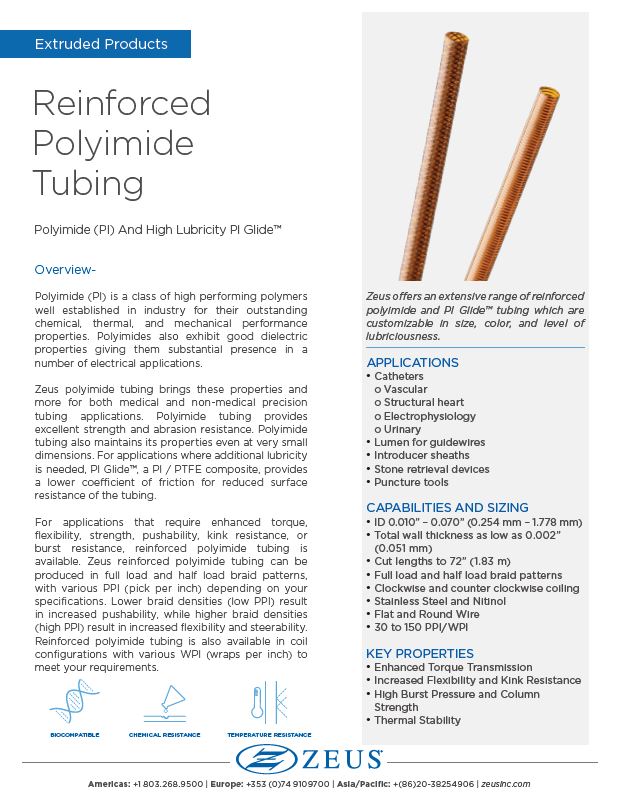

Reinforced Polyimide Tubing

Braid and coil reinforced polyimide tubing is available for challenging applications that require enhanced torque, flexibility, kink resistance, improved pushability, or increased strength. These features help medical device engineers optimize their device designs and fine-tune key performance characteristics, paving the way for improved procedural outcomes and increased patient safety. Reinforced PI tubing can be produced with full-load and half-load braid patterns, as well as clockwise and counter-clockwise coiling, with various PPI (pick per inch) and WPI (wraps per inch) to meet your design requirements.

Key Benefits of Reinforced PI:

- Improved Flexibility and Kink Resistance

- Improved Strength and Pushability

- Customizable Braid and Coil Patterns

Accelerate Your Speed-to-Market

With free samples available and short lead times to take advantage of, working with Zeus polyimide products enables you to bring your device to market quickly.

Product Sheet

Reinforced Polyimide Tubing

Capabilities, sizing, properties, & more.

Download Now

Product Sheet

Polyimide / PI Glide™ Tubing

Capabilities, sizing, properties, & more.

Download Now

Material Sheet

Polyimide

Properties, applications, & more.

Download Now

Request Samples

*Our thorough analytical test results indicate that no SVHC/CMR restricted substances are intentionally included in Zeus-supplied polyimide products at levels above the 0.1% threshold outlined by REACH and EU MDR.